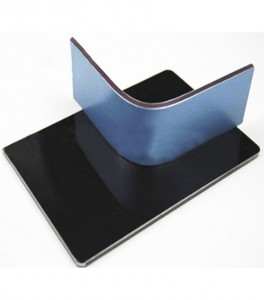

NEWCOBOND® Signage Panel for Signs & Billboard

STRUCTURE

ADVANTAGES

EXCELLENT PRINTING PERFORMANCE

Due to the UV printing coating on the surface, NEWCOBOND signage panels have very good adhesion force to printing ink which can ensure the durability of advertising designs.

FLAT&CLEAN SURFACE

NEWCOBOND signage panel used pure core materials to improve the surface’s flatness and cleanness, there are no bubbles or dots on the surface.

EASY PROCESSING

NEWCOBOND ACP has good strength and flexibility, it’s easy to transform, cut, fold,drill, curve and install them.

GOOD WEATHER-RESISTANCE

Surface treatment with high-grade ultraviolet-resistant polyester paint (ECCA) request, guarantee 8-10 years; if use the KYNAR 500 PVDF paint, guaranteed 15-20 years.

DATA

| Aluminum Alloy | AA1100 |

| Aluminum Skin | 0.18-0.50mm |

| Panel Length | 2440mm 3050mm 4050mm 5000mm |

| Panel Width | 1220mm 1250mm 1500mm |

| Panel Thickness | 4mm 5mm 6mm |

| Surface treatment | PE / PVDF |

| Colors | All Pantone & Ral Standard Colors |

| Customization of size and color | Available |

| Item | Standard | Result |

| Coating Thickness | PE≥16um | 30um |

| Surface pencil hardness | ≥HB | ≥16H |

| Coating Flexibility | ≥3T | 3T |

| Color Difference | ∆E≤2.0 | ∆E<1.6 |

| Impact Resistance | 20Kg.cm impact -paint no split for panel | No Split |

| Abrasion Resistance | ≥5L/um | 5L/um |

| Chemical Resistance | 2%HCI or 2%NaOH test in 24hours-No Change | No Change |

| Coating Adhesion | ≥1grade for 10*10mm2 gridding test | 1grade |

| Peeling Strength | Average ≥5N/mm of 180oC peel off for panel with 0.21mm alu.skin | 9N/mm |

| Bending Strength | ≥100Mpa | 130Mpa |

| Bending Elastic Modulus | ≥2.0*104MPa | 2.0*104MPa |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Temperature Resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropped≤10% | Change of glossy only.No paint peel off |

| Hydrochloric Acid Resistance | No change | No change |

| Nitric Acid Resistance | No Abnormity ΔE≤5 | ΔE4.5 |

| Oil Resistance | No change | No change |

| Solvent Resistance | No base exposed | No base exposed |

Write your message here and send it to us

Related PRODUCTS

-

Whatsapp

-

Whatsapp

WhatsApp

-

Top